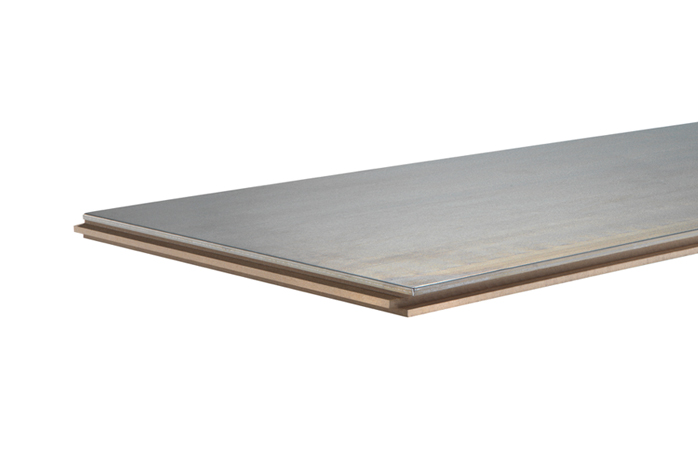

MetaGard® SST

Maximum durability

Stainless steel flooring surface for robotic traffic

A heavy-duty solution, MetaGard® SST was developed to accommodate the most intensive and heavy AGV and AMR implementations. MetaGard SST has been tested and verified to be up to five times as wear-resistant in busy traffic areas that are not routinely cleared of dirt and debris when compared to routine flooring solutions such as concrete. This makes MetaGard® SST the ideal solution for operations that are automatically performed by robotics without employee interaction, day in and day out. Our testing has shown MetaGard® SST to be able to withstand more than two million yearly pivots by loaded AGV’s changing direction, showcasing its resilience.

Best cost-to-performance-ratio

MetaGard SST are custom steel panels that cover the top and sides of each flooring panel. MetaGard SST will ensure a smooth panel-to-panel load transfer, even on ResinDek panels not equipped with metal covering. We would recommend installing MetaGard SST in the most heavily used areas in your facility in combination with TriGard ESD Ultra for the lesser and lighter-used paths for the best cost-to-performance ratio.

MetaGard SST has been tested and verified according to the following standards:

Dynamic Coefficient of Friction: ASTM A326.3

- Test Procedure: Neolite sensor has material that is 95+/-3 Shore A

- Results: Dry: 0.77 | Average Wet: 0.68

Taber Abrasion: ASTM D4060 (Wear Resistance)

- Test Procedure: Grit aluminium oxide sandpaper is replaced every 500 cycles with 1 kg of weight

- Results: Wear Rating: >50,000 cycles

Gouge Resistance: ASTM D2197

- Test Procedure: Tested with weights ranging from 1kg to 10.5kgs

- Results: No Failure

Light Reflectivity: ASTM D523 Gloss, 85 Deg

- Test Procedure: Tested with gloss meter geometries of 85°

- Results: 8 GRUs

The right flooring is the foundation of success.

Making the right choice for your flooring needs is key to ensuring optimal warehouse traffic performance.